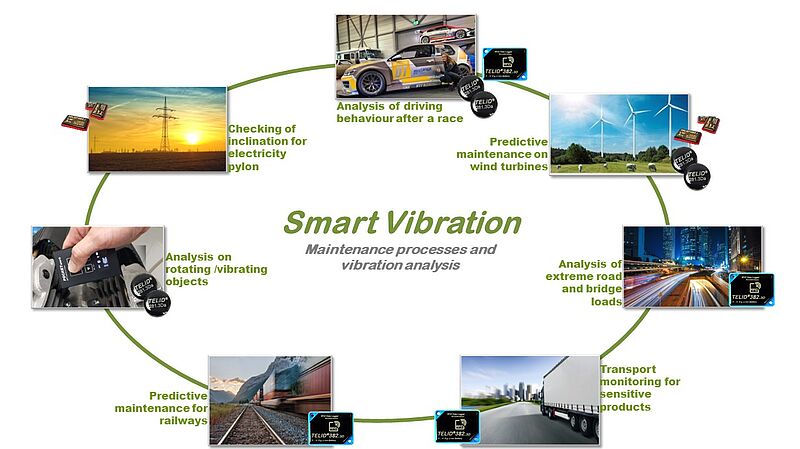

Smart Vibration

Maintenance processes and vibration analysis

In the maintenance and repair area, in transport logistics, but also in condition monitoring on production or energy systems, the detection of vibrations or shock events is playing an increasingly important role. After all, it helps us plan and save valuable resources. The use of the latest technologies will help us in the future to carry out these test tasks practically, quickly and with little effort.

microsensys offers two new independent system solutions to measure vibration, shock events and rotations. They differ fundamentally in the areas of application and handling, although they use the same sensor core and identical RFID communication interfaces.

Multifunctional contact and batteryless 3D vibration sensors with integrated analytics

Sensor-Transponder TELID®281.3Da

The new passive sensor-transponder TELID®281.3D measures 3D vibrations in a frequency range from 0 to 2.8 kHz with an acceleration resolution of only a few mg. It also analyzes radial and tangential accelerations and the speed of rotating shafts. To avoid large amounts of communication data, the small and lightweight sensor has its own integrated intelligence that evaluates 5D transients and can perform an in-situ Fast Fourier Transformation. Due to the contactless data transmission, the solution is used to advantage when monitoring the condition of moving parts such as shafts, motors, pumps, or roller bearings.

By means of a unique ID number and the existing EEPROM memory of the small and robust sensor transponder, the measuring point can be permanently identified, and readout cycles can be saved. You can find more technical details about our sensor transponders or mobile readers for your application in these sections: Product: Sensor-Transponder and Product: Mobile Reader

Schock Event Data Logger

Event-controlled shock and vibration measurement with TELID®382.3D

With the semi-passive data logger TELID®382.3D, shock events are recorded with a 3D swing over a defined period. The need for such a solution is enormous and is used in industry and logistics, in the railway sector or road construction. The events are triggered either by exceeding a preset threshold value or in preconfigured time intervals. The integrated battery, which only supplies the acceleration sensor and the real-time clock with energy, enables events to be recorded without a direct RFID communication device. After the data loggers have been collected, the data is read out using a licensed RFID reader in combination with the TELIDsoft 5.0 software solution, parameters are reinitialized, started or stopped and evaluated.

The main advantage of this solution is that it is flexible and easy to use. Based on the oscillation curve, material and environmental changes during use can be recognized at an early stage and necessary maintenance can be planned. Depending on the application, the loggers can be used for up to 3 years. Further information about our data loggers or mobile readers for your application can be found under Product: Data Logger and Product: Mobile Reader